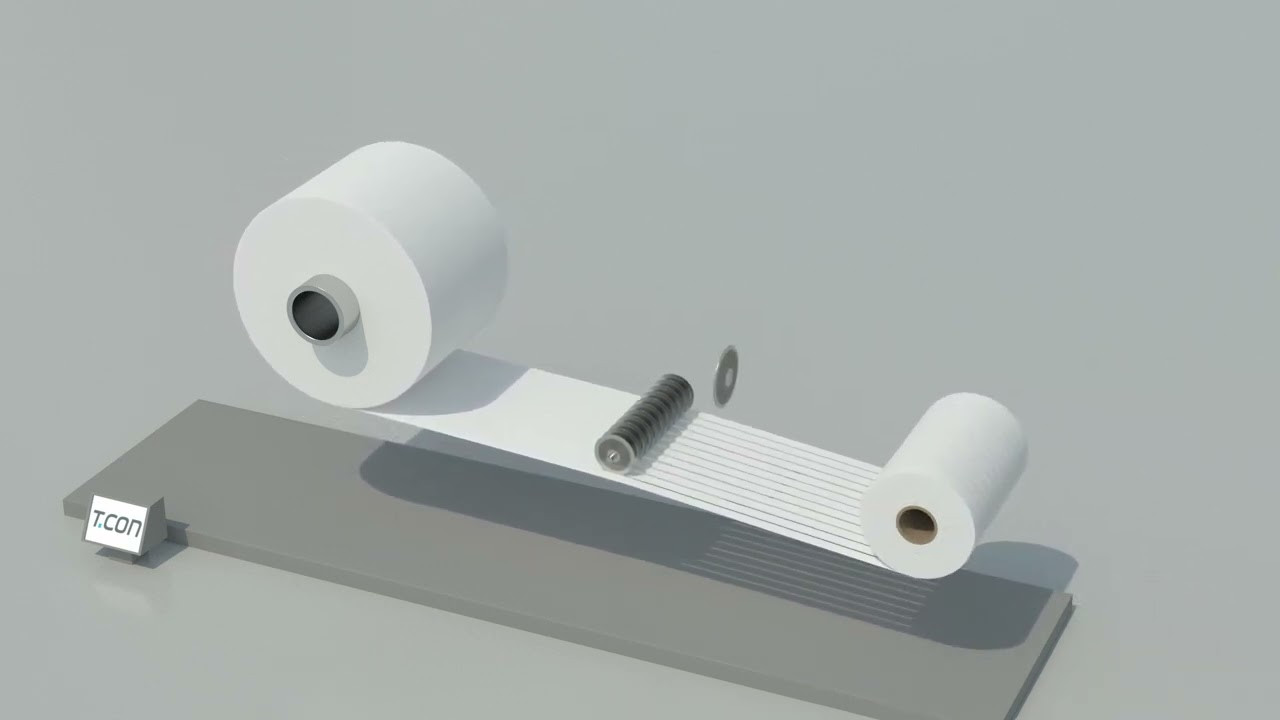

The methods a company employs to save money need to be ahead of the competition – With T.CON we will find you ways to save time and money. T.CON’s Trim Optimization enables our customers to reduce trim loss and waste with a fully featured deckle optimization tool. Companies in the mill industry are all struggling with the same problem: manual planning of cutting plans is time-consuming and does not always provide the optimal solution. Employees are busy for hours to optimize one single cutting plan.

What is the solution? T.CON’s TRIM SUITE is the world’s first tool to run natively and fully integrated in SAP. It is fully featured as well as integrated into your work process. TRIM SUITE creates and compares results within seconds, it is easy to use and can maximize savings by defining costs for various aspects of production, including material loss, knife changes, storage or yield.

![[Translate to English:] Verschnittoptimierung für Profile aus Metall oder Holz [Translate to English:] Verschnittoptimierung für Profile aus Metall oder Holz](/fileadmin/user_upload/05_Landingpage_TRIM_SUITE/TRIM-SUITE-Metall_Header.jpg)

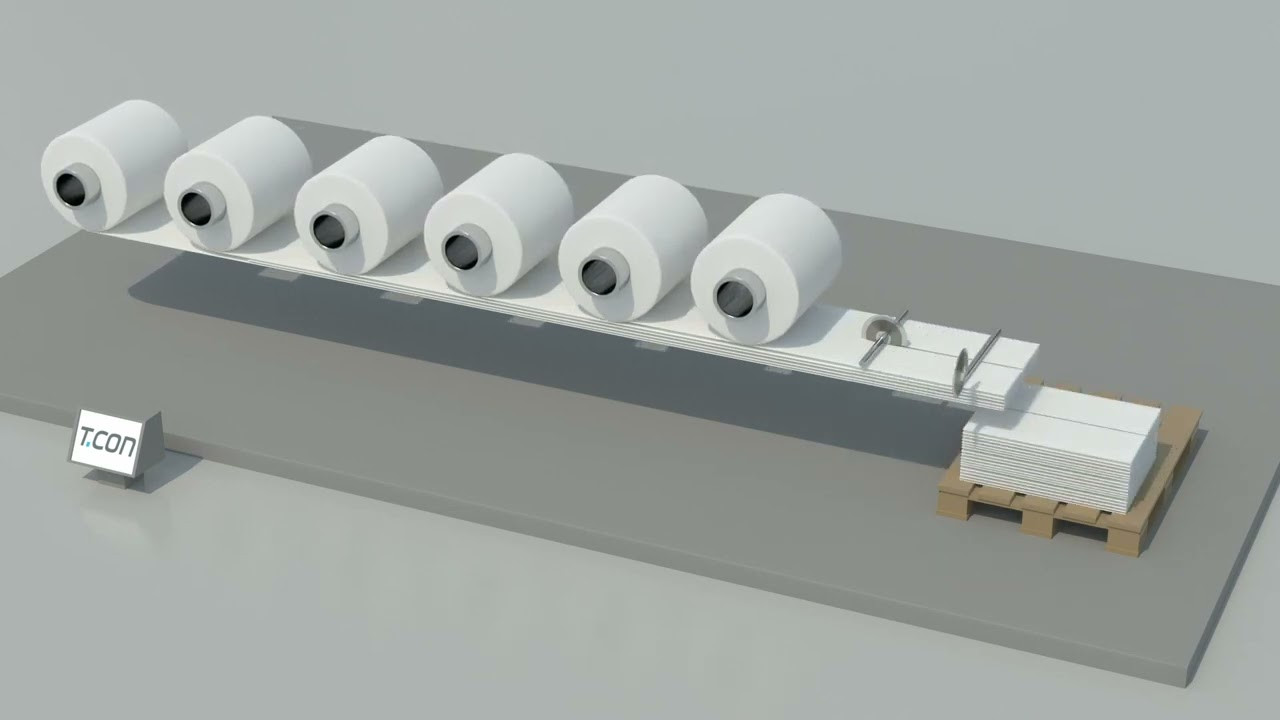

The mill industry isn’t the only sector where waste is an issue when cutting up intermediate products. Optimizing trim and minimizing waste is also vital for producers of one-dimensional products such as rods, pipes, cardboard tubes and profiles.

In the SAP world, these are known as ‘Long Products’ and the associated tools are ‘Long Product Planning’ (LPP) tools. And TRIM SUITE is the optimal solution in the LPP world, for any production material – steel, plastic, wood... TRIM SUITE can do it all.

![[Translate to English:] TRIM SUITE der T.CON: SAP Certified - Integration on SAP S/4HANA [Translate to English:] T.CON TRIM SUITE 2.0 jetzt von SAP zertifiziert](/fileadmin/_processed_/a/d/csm_Auszeichnungen_TRIM-SUITE_v1_5b7475026d.png)

Webinar: „Hear from Model AG how to optimize cutting plans for efficiency, transparency and profitability!“

The paper and packaging industry has been deeply affected by paperless technology. Differentiation is key. Find out in this joint SAP® and T.CON webinar how T.CON’s trim optimization solution TRIM SUITE can help boost your business. Running natively and fully integrated in SAP®, it gives you flexibility to produce optimum quantities. Firsthand customer experience and a live demo will highlight its saving potential.

Experience how TRIM SUITE from T.CON can solve your problems with the newest generation of cutting plans quickly and automatically. TRIM SUITE takes advantage of a number of features, options and parameters of your production to provide you with the optimal result. Brad, a T.CON consultant in TRIM and MES, has the pleasure to show you how quickly and easily it is to generate a cutting plan with our solution.

The T.CON consultants understand the exact requirements for the paper industry. Their familiarity with the industry is part of the reason a tool like TRIM SUITE models our needs so well.

Sönke König, Team Leader for Production Planning at Steinbeis Papier GmbH

![[Translate to English:] Referenz Steinbeis | T.CON](/fileadmin/_processed_/9/2/csm_Referenzen_BI_steinbeis_dfe587178c.jpg)

Steinbeis Papier is one of the leading manufacturers in the paper recycling industry in Europe. For many years, they have been using SAP ERP and SAP APO for their supply chain. In 2015, T.CON’s TRIM SUITE was integrated and replaced the outdated solutions for trim optimization and an external MES system.

TRIM SUITE is integrated as useful heuristics in the APO Detailed Scheduling. Cutting plans are seamlessly sent to the MES CAT system for starting production. Without any external interfaces, the full order-to-cash process can be done with standard applications by SAP and T.CON, based on 100 percent SAP technology.

Delfortgroup is the world leader in design, development, manufacturing and promotion of thinner, more sustainable and tailor-made speciality papers for the tobacco industry, pharmaceutical and food industry. Delfortgroup AG is based in Traun (Austria). They also produce thin print paper for package information leaflets, religious literature and catalogues as well as label base paper and electrical insulation paper. With over 2,000 employees all over the world, delfortgroup has six production mills in Austria, the Czech Republic, Hungary, Finland and Vietnam with five subsidiaries in Germany, France, Great Britain, the USA and China.

Delfortgroup expanded its business in 2016: Mundet with operations in the USA and Mexico as well as delfortgroup printing services Inc. belong to delfortgroup now. TRIM SUITE was implemented in their site in the Czech Republic in October 2016. Product planning is made in a customized block planning in SAP ERP. Seamless integration of Trim Connector in ERP and planning processes so that best results can be achieved. Entire blocks of orders with up to 80 orders in one cutting plan are daily business. Cutting plans are seamlessly sent to the MES CAT system for starting production.

Using TRIM SUITE by SAP Gold Partner T.CON, Perlen Packaging integrates its cutting plans in SAP S/4HANA. This means the company is benefiting from an IT-supported, efficient and transparent system, fully coordinated with T.CON's SAP-based MES CAT suite.The result: the pharmaceutical blister packaging manufacturer is increasing productivity in its plants and reducing technical waste and material costs.

“The core objectives of our growth-oriented corporate strategy include continuous optimization of our business processes, optimum capacity utilization in our plants, and a steady reduction in costs”, explains René Kuhn, Head of IT at Perlen Packaging.

You can also submit your questions by filling out the following form.

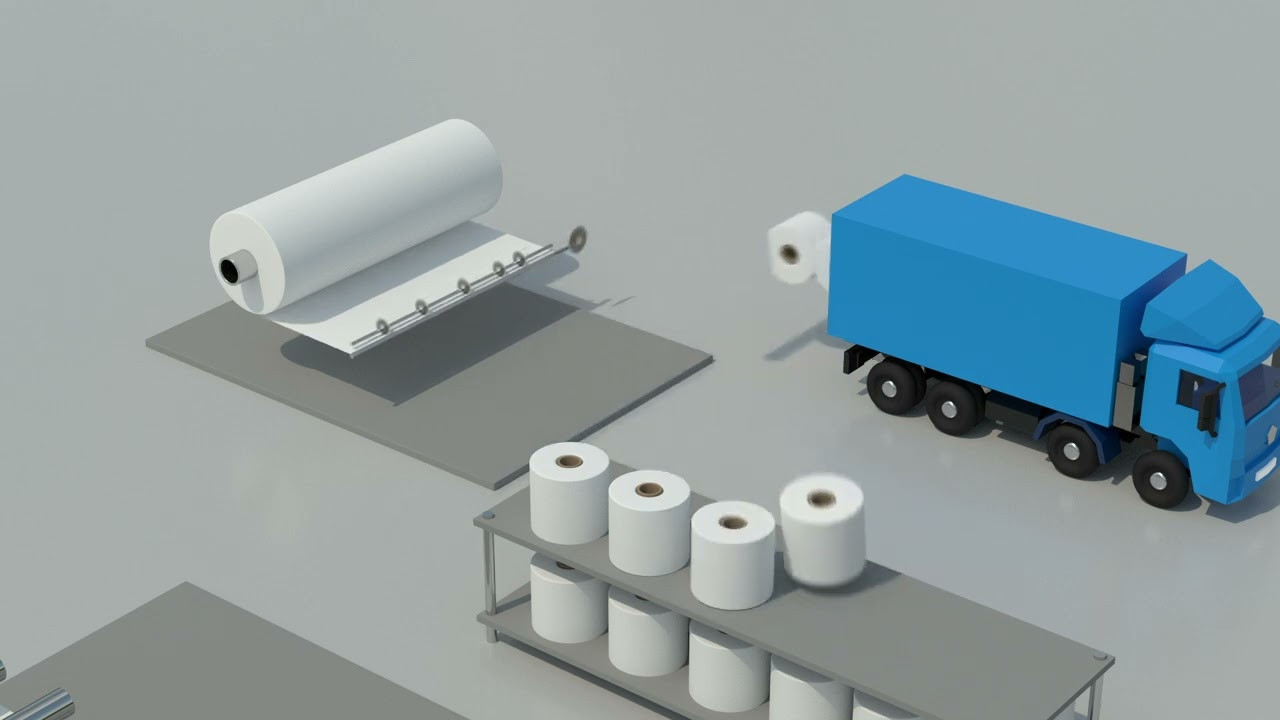

TRIM SUITE is a full-featured optimization application for creating patterns and cutting plans for reels, sheet, corrugated products, and long products. It is an exceptionally efficient tool for trim optimization.

TRIM SUITE is an application running inside SAP, based on SAP technology. In SAP PPDS Trim Suite is offered as a heuristic that can be utilized from any planning application such as detailed planning board, product view, or planning run. Combined orders are created as a result to reflect what dimensions and quantities will be produced in parallel. Cutting patterns are stored with respect to those combined orders. Cutting patterns are integrated with a Manufacturing Execution System such as MES CAT.

TRIM SUITE allows optional and binary optional planning of orders, single-level and multi-level optimization (primary and secondary cutting operations). It automatically considers existing stock during optimization and, in the case of quality trimming, defects in existing stock. It supports the production planner by automatically creating sets of solutions and by creating and comparing multiple solutions.

Planning processes in Excel are error-prone and time-consuming. TRIM SUITE provides easy, efficient, and fast trim optimization by automatically creating patterns and cutting plans with one click - it supports production planning to optimally combine orders. TRIM SUITE is easy to learn with an innovative user interface and has a visually appealing and clear graphical user interface that makes trim optimization a simple task.

The benefits of using TRIM SUITE for trim optimization include reducing trim loss and/or waste with best-in-class planning functionality, minimizing setup times by assigning penalty costs for knife changes, maximizing production efficiency and resource utilization, producing the optimum quantity to best serve the customer, reducing inventory by integrating existing inventory, production, or purchases as part of the optimization, and avoiding errors by integrating checks on order attributes and technical limitations of resources.

TRIM SUITE can be used for trim optimization in reel and sheet production, e.g., in paper, board, film, metals, and fiber production. Trim optimization also enables efficient and sustainable production of long products such as profiles, tubes or poles cut from any type of material.

Beside the functional benefits (quality of optimization results, full coverage of detailed technical requirements) there are benefits for an IT perspective and from a user perspective.

For users/business: Trim Suite is fully integrated into SAP’s planning application and is just another planning feature (in PPDS: another heuristic) within SAP standard. Planners start trimming from their main planning applications, they stay inside their SAP system (same look and feel), and results from trim optimization are automatically modelled within SAP planning by using SAP standard features. There is no logon to any other software tool, no data transfer, no delay, no loss of data.

From an IT perspective a lower total cost of ownership (TCO) is a main advantage. No additional hardware/servers are needed for trim optimization, as Trim Suite is running entirely on the SAP technology stack. Installation and setup are also done in fully alignment to SAP standard (master data and customizing). Even project specific enhancements are done in alignment with SAP’s enhancements concept (Appends, BAdI), and can even be done by IT staff on customer side.

The implementation of T.CON's TRIM SUITE usually takes about one week. This depends on the complexity of the project and the existing systems. Our expert consultants are available to work with you to ensure a smooth implementation process.

Yes, TRIM SUITE is long product ready and works with Long Product Planning.

T.CON's TRIM SUITE is the optimal solution for companies looking for a comprehensive optimization application for creating patterns and cutting plans for reel and sheet goods. The suite is designed to help reduce trim loss/waste and minimize setup times. It can also create combined orders, produce optimum quantities, reduce overall inventory costs, reduce inventory, and eliminate errors. Companies in the millwork industry, as well as those producing one-dimensional products such as rods, tubes, and profiles, can benefit from this software.

TRIM SUITE works with both SAP ERP and SAP S/4HANA. It can be utilized within PPDS as a planning heuristic. It can be utilized in PP from the production order information system.